|

2003

Maine Wastewater Salary Survey as conducted by the Maine Wastewater Control

Association

2003 Maine

Wastewater Rate Survey conducted by the Maine Rural

Water Association

Maine DEP Monthly

O & M Newsletter

Maine and WEF's

Operation Forum

Penobscot Watershed and Development of a TMDL

EPA Binational Toxics

Strategy

Maine Rural Water

Association

Maine Wastewater

Operator Certification

Guide

Maine Is Technology

Newsletter

Maine

Wastewater Control Association

Maine

Wastewater Engineering

Firms

| |

AERATED

LAGOON TECHNOLOGY

by

Linvil G. Rich

Alumni Professor Emeritus

Department of Environmental

Engineering and Science

Clemson University -

Clemson, SC 29634-0919 USA

Email: lrich@clemson.edu;

Tel. (864) 656-5575; Fax (864) 656-0672

Technical Note Number 7

MIXED-LIQUOR RECYCLE (MLR)

LAGOON NITRIFICATION SYSTEM

As

was discussed in Technical Note 6, during warm summer months, some

nitrification generally occurs in most aerated lagoons. However, such

nitrification is usually unpredictable and cannot be depended upon to meet

effluent limits, especially during the winter months. Therefore, for aerated

lagoons to be considered as viable processes for nitrification, the lagoon

process must be modified so that the solids age is uncoupled from the hydraulic

retention time (HTR). This can be accomplished either through sedimentation in

clarifiers with solids recycle or through the retention of the solids in the

aeration basin by use of sequencing batch reactor (SBR) technology. The latter

approach has been used in single basin, continuous-feed, intermittent discharge

(CFID) treatment systems for many years both in Australia and the United States.

Their performance has been well documented (Goronszy 1979, Arora et al.,

1985, Deeney et al. 1991). Although generally successful, some of the

CFID systems have had major operational problems as the result of

short-circuiting and/or sludge bulking. However, such problems can be minimized,

or even eliminated, by modifying the design to deal directly with conditions

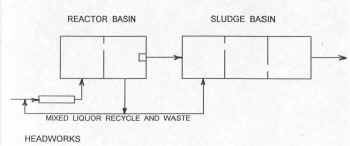

that promote the problems. The mixed-liquor recycle (MLR) lagoon system

incorporates such modifications. The MLR nitrification system, which is not

proprietary, is illustrated in Fig. 1. The system consists of two earthen basins

in series – a reactor basin for ammonia and CBOD5 removal and a

sludge basin for solids stabilization and storage. The overall configuration and

size of such a system are discussed in the following paragraphs. Design details

are to be found in Rich (1999).

REACTOR BASIN

The reactor basin is divided into two cells by

a floating curtain wall or a hard wall. The first cell is aerated continuously,

whereas the second cell is aerated intermittently in a controlled cycle that

includes sedimentation and supernatant decant. Mixed liquor is recycled from the

second cell to a manhole just upstream from the headworks of the plant. There it

is mixed with the incoming sewage. The mixture flows through the headworks and

into the first cell in a continuous stream. The two cell configuration

eliminates short circuiting through the reactor basin as well as modulates the

peaks of the diurnal loading pattern. Furthermore, by designing for

nitrification to occur in the second cell, the system separates the oxygen

demand of nitrifiers from that of the heterotrophs creating more favorable

conditions for nitrifiers. The mixed liquor recycle promotes the contact of the

biomass with the soluble CBOD5 in the sewage, thus reducing the

tendency for filamentous bulking.

The nitrification process is controlled

through the continuous wasting of the mixed liquor from the reactor basin to the

sludge basin. Such control can be accomplished by diverting a portion of the

recycle flow. The flow rate of the diverted mixed liquor will determine the

solids retention time at which the process is operated. The rate can be

controlled simply by adjusting a hand valve inserted in the piping for the

diverted flow.

In addition to aeration equipment and mixers

to ensure solids suspension, equipment required includes a programmable logic

controller (PLC), liquid level sensors, a low-head recycle pump, and a decant

device. The latter can be as sophisticated as a decanter designed for sequencing

batch reactor technology, or as simple as pumps or fixed pipes with automatic

valves.

The design retention time in the reactor basin

should be such that sufficient volume is provided to dilute peak organic and

ammonia loads, yet low enough to reduce the power requirements for solids

suspension. Therefore, it is recommended that the retention time at design flow

rate, HRTD, be a function of the ratio of the initial flow rate, QI,

and the design flow rate, QD. If QI/QD >

0.5, then HRTD should be 2d. If QI/QD < 0.5,

then HRTD should be 1d.

SLUDGE BASIN

The sludge basin is designed for solids

stabilization by benthal processes and multiyear sludge storage. Furthermore,

the basin serves as an effluent balance tank to attenuate the intermittent

decants from the reactor basin. Two floating curtain walls are used to divide

the basin into three cells, each with a hydraulic retention time of about one

day at the design flow rate. All cells are aerated, but not at a rate that

interferes with sedimentation. Aeration is required in the sludge basin to

prevent ammonia feed back from the bottom solids, and to eliminate dead spaces

in the water column where algae can become established and grow. If QI/QD

> 0.5, then the HRTD should be 3d. If QI/QD

< 0.5, then the HRTD should be 2d.

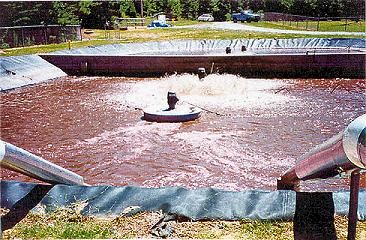

EXISTING SYSTEMS

Although the MLR nitrification system must still

be considered innovative, two such systems are currently in operation and a

third is under design. The two systems in operation are located close to

Liberty, SC. The Cramer lagoon initially was a dual-power, multicellular aerated

lagoon system consisting of a separate reactor basin followed by a sludge basin

divided into three cells in series. The upgrade consisted of dividing the

reactor basin into two cells in series with a hard wall, fitting both cells with

aerators and mixers, providing a decant pump and line to the sludge basin, and a

mixed liquor recycle pump and a line to a manhole above the headworks of the

plant. A programmable logic controller (PLC) was installed to control aerators,

mixers, and pumps. At the present, discharge from the second cell of the reactor

is on a six-hour cycle. The Cramer system is permitted at 157,000 gal/d. Cost of

the upgrade was $312,000. Photographs of the Cramer lagoon system are shown in

Fig. 2.

Initially, the Roper lagoon was a single-basin,

facultative aerated lagoon. The upgrade consisted of dividing the existing basin

into two cells in series with a floating curtain wall, fitting both cells with

aerators and mixers, a decant pump and line to a new sludge basin, and a recycle

pump and line to a manhole above an enlarged headworks. The upgrade included

also a new three-cell sludge basin, with aerators, and an enlarged

chlorination-dechlorination facility. A PLC was installed for control of the

aerators, mixers and pumps. The Roper system is permitted at 500,000 gal/d. Cost

of the upgrade was $1,100,000.

Figure 1.

Mixed-liquor recycle (MLR)

nitrification system

Reactor basin with first cell in foreground

Closer view with decant and mixed-liquor recycle

pumps in left background

Second cell of reactor basin in foreground with headworks in

far background

Three-cell sludge basin with chlorination facilities in far

background

Figure 2.

Photographs of the Cramer mixed-liquor nitrification system at Liberty, SC.

REFERENCES

Arora, M. L. et al.

(1985). “Technology evaluation of sequencing batch reactors.” J. WPCF,

57(8),867-875.

Deeney, K. et al.

(1991). “Implementation of sequencing batch reactor technologies in the United

States.” 64th Annual Conf., WPCF, Toronto, Canada.

Goronszy, M. C. (1979).

“Intermittent operation of the extended aeration process for small systems.”

J. WPCF., 51(2),274-287.

Rich, L. G. (1999).

High-Performance Aerated Lagoon Systems. American Academy of Environmental

Engineers.Annapolis, MD.

|